hakupur ®

Advanced Aqueous Cleaners

Technology

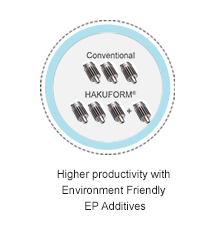

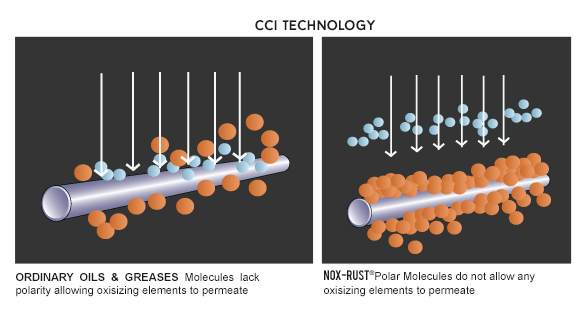

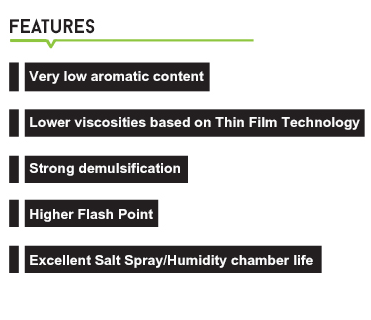

HAKUPUR ® cleaners harness the power of multi-functional Power Surfactants (combination of non-ionic and Cationic surfactants ) to deterge versatile organic & inorganic soils.

Special Dual Effect Action enables HAKUPUR® cleaners to combine the power of emulsification (carrying off the soil/dirt from the components) & demulsification (separating out soil/dirt from cleaner to its surface for skimming) even at lower temperatures compared to conventional cleaners.

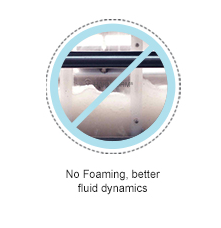

HAKUPURⓇ Cleaners reduce the surface tension by adsorption at the liquid-gas interface. This dynamics induces superb cleaning effect without compromising on the critical factors for industrial applications such as foaming where bubbles or drops are rapidly generated and need to be stabilized.

Benefits

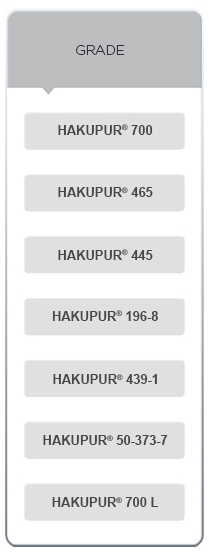

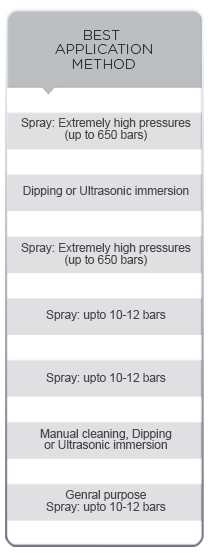

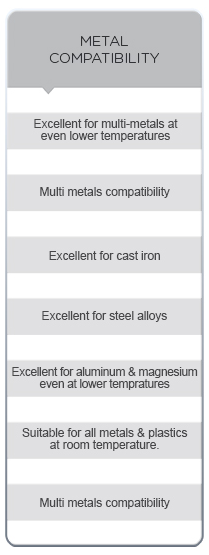

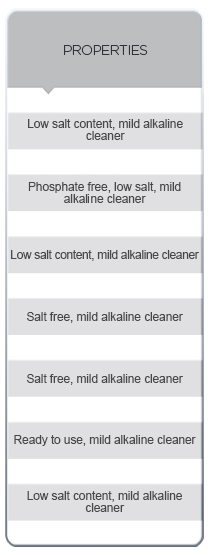

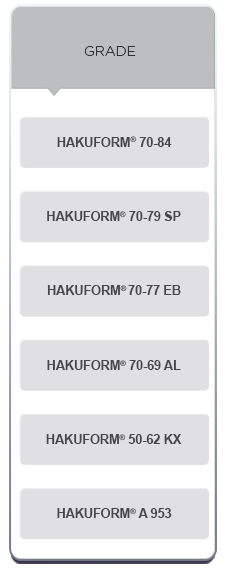

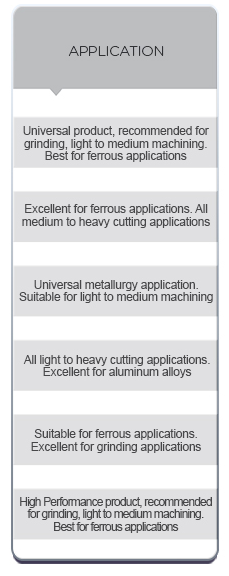

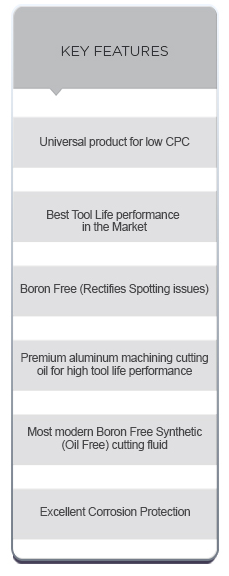

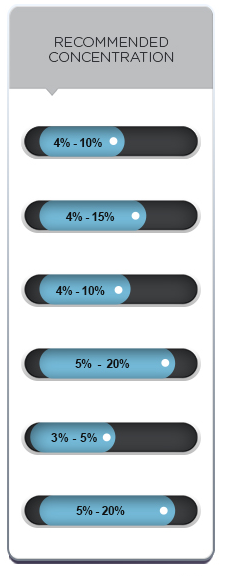

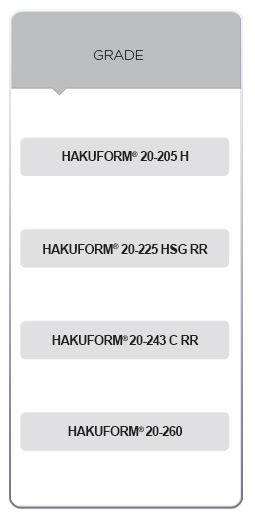

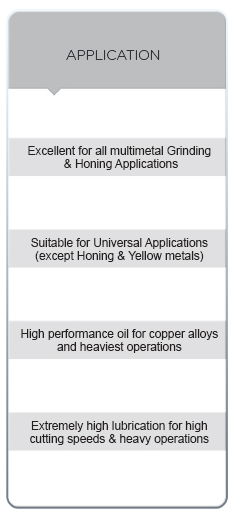

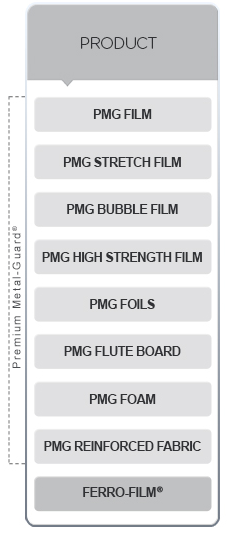

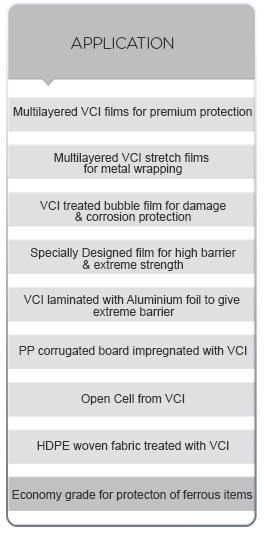

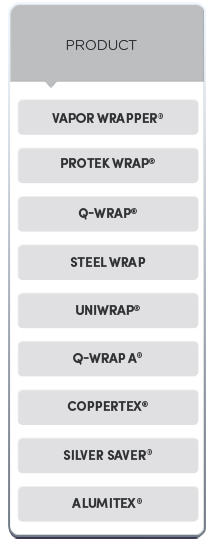

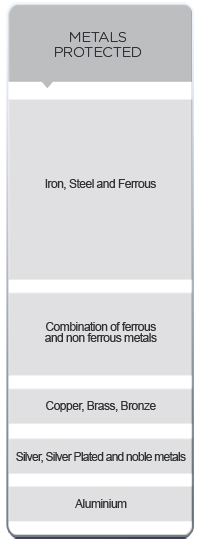

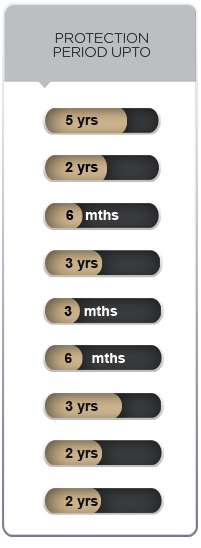

Product Guide