Cutting Tool

Our Products

Product Name

Product Image

Features

Product-details

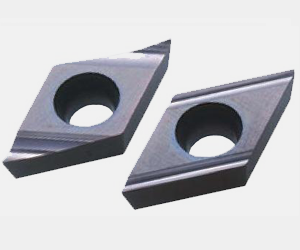

ISO Inserts

- Inserts are removable cutting tips, which means they are not brazed or welded to the tool body. They are usually indexable, meaning that they can be exchanged

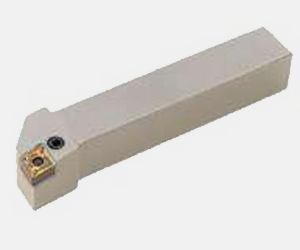

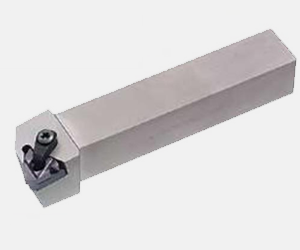

ISO HOLDERS

- Lever Lock Type

- ISO Standard

- Various holder shapes.

- Suitable for light to Heavy Cutting

- Economical Negative insert

THREADING ID

- Various insert types

- M-class 3-D breaker inserts and G-class ground inserts available

- Available with a wiper cutting edge to provide a precise thread geometry

Boring Bars

- Solid Carbide type with two cutting edges

- Continuous cutting from boring to facing

- with or without a chip breaker

SMALL TOOLS

- ISO E class accuracy inserts

- A wide variety of small corner R inserts

- Rake angle 30°

Grooving

- Corresponding blades to a variety of modular holders with different shank sizes

- Wide selection of holders and inserts available for diverse grooving and cutting off applications

CBN & PCD

- Multi-corner Type Double Sided

- Multi-corner Type Double Sided with Wiper

- Multi-corner Type Double Sided with Breaker

Drilling

- As there is no chinsel edge, the results are high centripetal force and small hole oversize

- Requires a special grinding machine

Exchangeable Heads end mill

- Ultra Micro Grain Carbide

- End Cutting Edge with Coolant Hole

- Peripheral Cutting Edge with Coolant Hole

- Sharp Corner Edge

Rotating Tools Inserts

- The micro-grain wear resistant AI2O3 and fibrous TiCN layers deliver excellent wear resistance in high speed cutting.

- Use of a specially developed cemented carbide

Indexable Milling

- The micro-grain wear resistant AI2O3 and fibrous TiCN layers deliver excellent wear resistance in high speed cutting.

Brazed Tips

- the brazed tools provide a cutting surface with the combined characteristics of compressive strength, extreme hot hardness at high temperatures, and resistance to abrasion

BASIC HOLDERS

- The HSK-T type has a closer tolerance between the spindle key and tool holder keyway than the HSK-A type

- This results in higher cutting edge