Industrial

Agriculture Oil

Compressor Oil

Gas Engine Oil

Heat Transfer Oil

Hydraulic Oil

Industrial Gear Oil

Industrial Grease

Metalworking Fluid

Mould Oil

Open Gear Oil

Paper Machine Oil

Railroad Engine Oil

Rock Drill Oil

Transformer Oil

PETRONAS Gear STR is a premium quality R&O industrial gear oil specially formulated for the lubrication of plain and anti-friction bearings, gears and crank mechanisms in which lubricants with extreme pressure (EP) and detergent properties are not required.

It is manufactured from specially selected premium quality base oils for their oxidation stability and water separating characteristics, and further fortified with selected oxidation and corrosion inhibitors to ensure long lasting protection. It is available in ISO 32 through ISO 460 viscosity grades.

Superior thermal and oxidation stability to resist oil degradation and thickening for longer oil service life.

Rapid water separation and anti-foam properties to ensure trouble-free operation.

Specially selected additive system prevents the formation of damaging deposits, varnish and rust.

Its additive system will not corrode bronze or silver components.

Recommended for the lubrication of enclosed gears, mobile or stationary hydraulic systems and non-turbine circulating oils where an EP type of lubricant is not required.

Highly recommended for industrial equipment requiring R&O type oil such as electric motor bearings, blowers, pumps, compressors and machine tools. It is particularly recommended for lubrication on bronze on steel worm gears.

The lighter grade is for used in bearings and gears working under high speeds and low loads while the more viscous grades are for bearings, cranks and gears working under low speeds and high loads as well as for high pressure compressors.

ANSI/AGMA 9005-D94 R&O Grade (0 to 7)

| Characteristics | ISO Viscosity Grade | ||||

| 32 | 46 | 68 | 100 | 150 | |

| AGMA Grades | 0 | 1 | 2 | 3 | 4 |

| Density @ 15 °C, kg/l | 0.892 | 0.893 | 0.895 | 0.896 | 0.897 |

| Pour Point, °C | -9 | -9 | -9 | -9 | -9 |

| Flash Point °C | 219 | 225 | 231 | 252 | 255 |

| Kinematic Viscosity, cSt | |||||

| @ 40 °C | 32 | 46 | 68 | 100 | 150 |

| @ 100 °C | 5.3 | 6.6 | 8.5 | 11.1 | 14.6 |

| Viscosity Index | 95 | 5 | 95 | 95 | 95 |

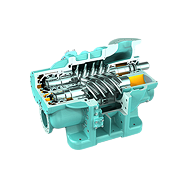

PRESSOL SYN RS Series are high quality non-toxic synthetic compressor lubricants. These series are based on synthetic hydrocarbons (PAO), formulated with FDA approved ingredients only and approved by the USDA for applications where incidental food contact may occur.

PRESSOL SYN RS series meet USDA H1 approval with NSF International for use in food and beverages processing plant applications.

Non-toxic

Less compressor maintenance

Excellent oxidation resistance

Excellent anti-wear properties

Fewer oil changes

Lower oil consumption

Reduced varnish lacquering and deposits

Greatly reduced fire and explosion hazard

Compatible with compressor seals, gaskets, hoses and air system components.

PRESSOL SYN RS series are recommended for all types of compressors where incidental food contact may occur with oil in the discharge air.

May also be considered for other applications requiring an oxidation resistant lubricant.

PRESSOL SYN RS series are available in viscosity range from ISO VG 32 to 150, make it an ideal lubricant for many applications in the food processing industries. For example: chains, hydraulic, pumps, gear-motor and bearings.

Nominal operating Range is -37°C to 180°C

18 Liters pail, and 209 Liters drum

PRESSOL SYN RS series are compatible to mineral oil and is similar to mineral oils in their compatibility with paints, seals, gaskets and hoses. No special precautions related to compatibility required when changing over from a mineral oil lubricant to a PRESSOL SYN RS synthetic hydrocarbon based lubricant.

PRESSOL SYN RS synthetic lubricants are field tested, approved or recommended by most major compressor manufacturers. Should you have any questions regarding the suitability of PRESSOL SYN compressor lubricants for a specific manufacturer's model compressor, please contact PETRONAS DAGANGAN BERHAD.

| Characteristics | Grade | |||

| IG-46 | IG-68 | IG-100 | IG-150 | |

| Viscosity, cSt | ||||

| @40°C | 47.8 | 67.7 | 96.4 | 142.0 |

| @100°C | 7.9 | 10.2 | 12.9 | 17.1 |

| Specific Gravity @15.6°C | 0.83 | 0.83 | 0.84 | 0.84 |

| Viscosity Index | 135 | 136 | 131 | 130 |

| Pour Point (max.), °C | -57 | -55 | -50 | -46 |

| Flash Point (min), °C | 240 | 240 | 240 | 260 |

| Autoignition Temperature, °C | 385 | 385 | 388 | 392 |

| Evaporation,22hrs, 99°C, % | <1 | <1 | <1 | <1 |

| Demulsibility, ml, Oil/water/emulsion (min) | 40/38/2(10) | 40/38/2(10) | 40/38/2(10) | 40/37/3(10) |

| Foaming tendency | NIL | NIL | NIL | NIL |

| Four Ball Wear Test, mm | 0.35 | 0.35 | 0.35 | 0.33 |

| Copper Corrosion | 1a | 1a | 1a | 1a |

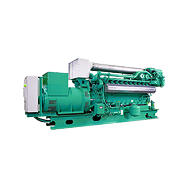

PETRONAS Danol XHT is A high quality heat transfer oil formulated for use in most direct and indirect fired heat transfer systems with forced circulation where the fluid is subjected to the most severe operating conditions. It is made from premium quality high viscosity index paraffinic base oils for their excellent heat transfer properties (specific heat and thermal conductivity) at all temperatures to provide more rapid heating and greater system flexibility. A thermally stable oxidation inhibitor additive is added to enhance its outstanding thermal and oxidation stability which can easily resist thermal cracking and chemical oxidation and maintain in solution any decomposition product that forms to maintain heat transfer system efficiency.

Outstanding resistance to thermal cracking and oxidation thus preventing excessive sludge and coke deposits formation for longer oil service life.

High thermal conductivity - heats quickly for fuel economy and even heat distribution.

Low vapour pressure - minimized fluid loss due to evaporation, vapour lock and hazards of flammability.

Low temperature start-up for prompt circulation.

Non-corrosive to aluminium, brass, bronze, copper and steel.

For use in both open and closed heat transfer systems with forced circulation. For closed systems, maximum heater outlet temperature is 305 °C and maximum heater wall temperature is 320 °C.for any open system, the operating temperature shall not exceed 200 °C for safety purposes

When starting up a new unit or restarting a unit after maintenance work or operating a unit irregularly, the temperature of the unit should be reduced to around 100 °C to allow steam blow off before returning to the normal operating temperature.

HIDRAULIK SYN PE 68 synthetic hydraulic fluids are formulated from high quality biodegradable synthetic base stocks.

They are recommended for most types of hydraulic systems using vane, gear, and piston-type pumps operating at extremes of both temperature and pressure. They afford a higher margin of safety to the environment should a line rupture or an accidental spill occur while at the same time offering performance and reliability superior to traditional mineral or vegetable-oil based fluids.

Improved pumping efficiency

Excellent high & low temperature stability

Excellent compatibility with materials of construction

Improved wear protection at elevated temperatures

Lower deposit formation in high temperature systems

Extended service life and longer drain intervals

High degree of chemical stability

Eliminates degradation and sludge formation

associated with conventional mineral oilsGreater margin of safety from fire and explosion.

Agricultural, construction, forestry and marine industries.

Mining, dredging and offshore oil production.

Recommended for use with piston, vane, and gear-type hydraulic pumps operating at extremes of temperature and pressure where a readily biodegradable, ecotoxicologically friendly fluid is desirable.

In 209 Liters Drum.

HIDRAULIK SYN PE is compatible with the following seal and elastomeric materials: Viton, High Nitrile Buna N, Nylon, Delrin, Celcon, PBT, Oil-Resistant Alkyd & Teflon.

Call PETRONAS Company for guidance if you have other questions regarding compatibility.